Field

Monitoring

Overview

Cutsforth has combined Premium Shaft Ground Monitoring and Rotor Flux Monitoring systems into one powerful Generator Field Monitoring system. By combining the functionality into a single platform, customers can achieve the benefits of both systems in one program integrated into InsightCM™ for better trend data and easier system management:

Allows for Condition Based Maintenance

- Can extend time between maintenance events

- Fewer forced outages

Reduces operating costs

- Eliminates annual outsource expenses

- Predicts conditions that can lead to failures

- Plants own and control their own data

- The system passes all data to the InsightCM data platform

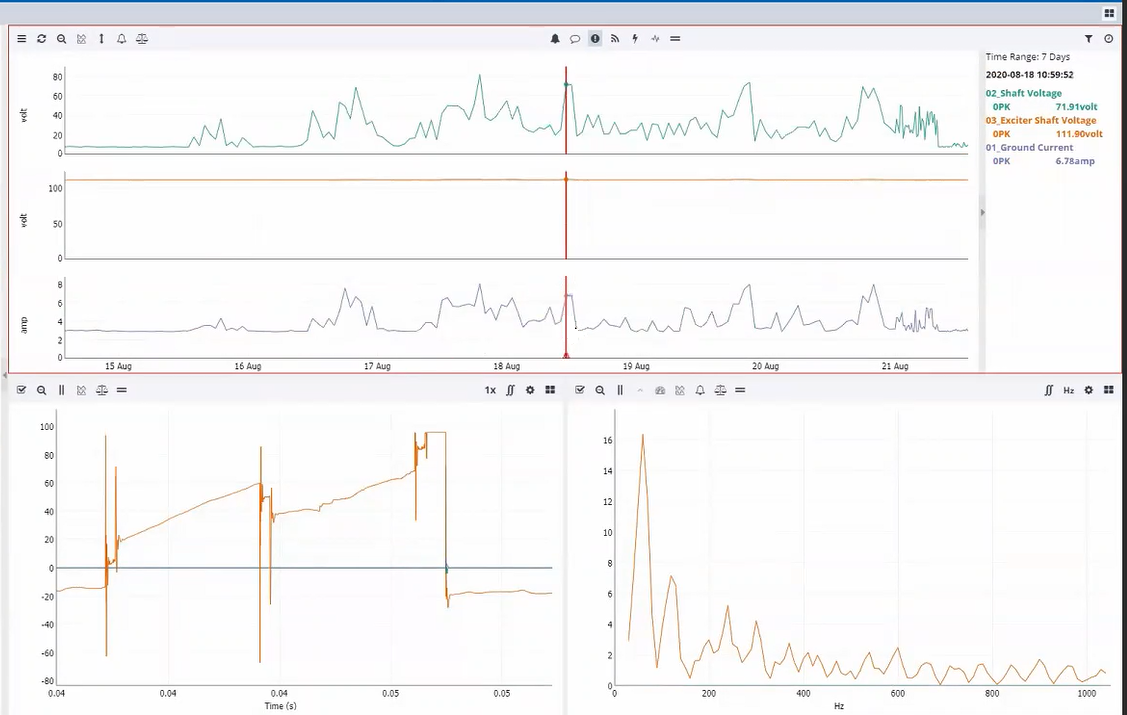

Cutsforth Premium Monitoring measures shaft voltage and current, while offering waveform capture and multi – feature alarm conditions. The system utilizes Cutsforth patented braided copper ropes for best in class grounding and data collection to detect:

- Poor Shaft Contact

- Bearing Failure

- Stator Insulation Failure

- Exciter Insulation Failure

- Ground Neutral Failure

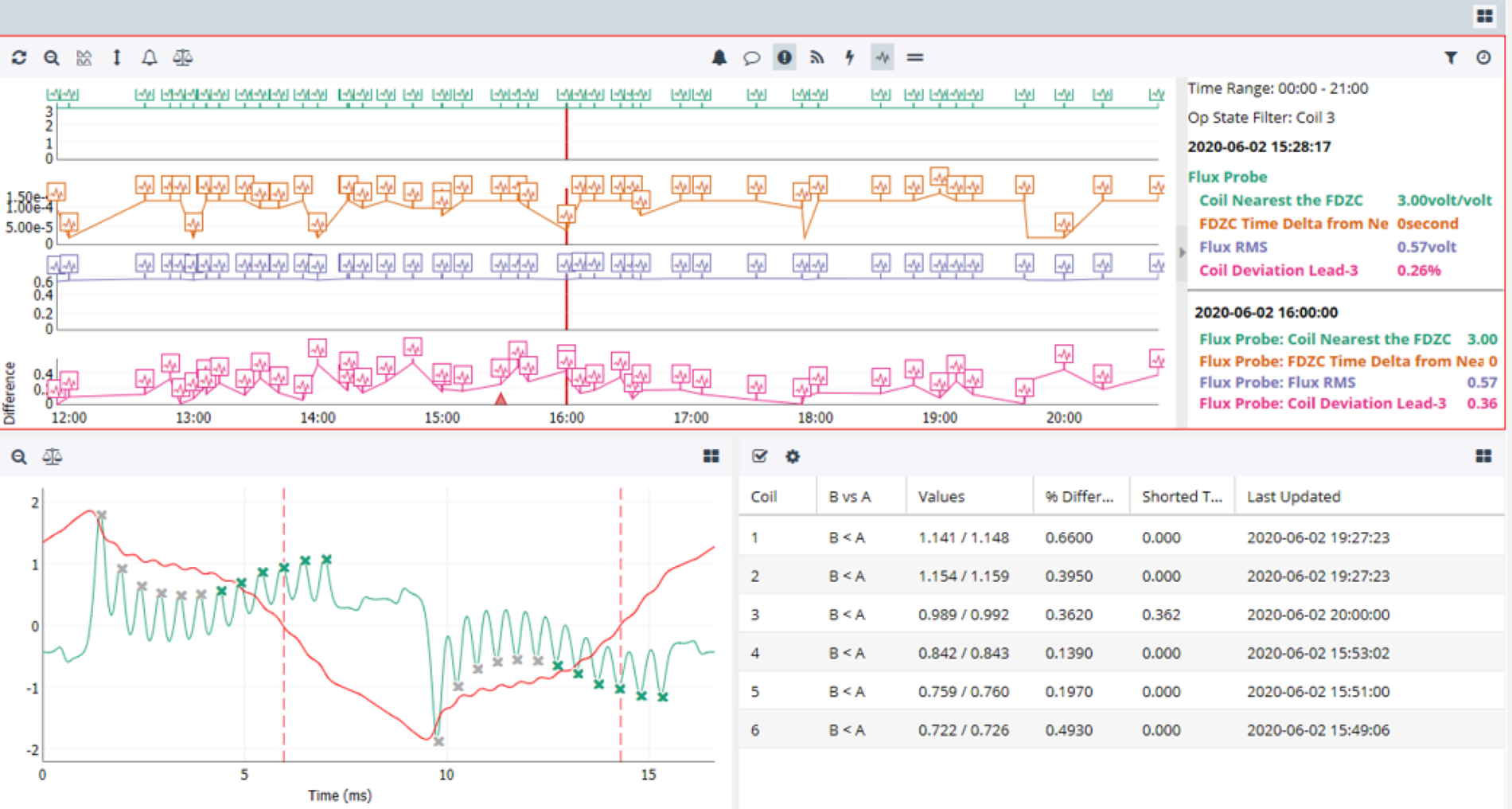

Variances in the magnetic flux within a generator indicate deterioration of winding insulation. Imbalances within the rotor can damage insulation, degrading the generator’s output capacity and increasing vibrations. This further damages the insulation, leading to a forced outage. The system allows plants to detect variants early, and trend them over time:

- High – speed samples identify shorted turns

- Creates a generator health trend, and archives data:

- Identifies worsening shorts through real-time and historical measurements

- Provides early indication conditions leading to rotor ground faults

- Easy to install and does not require an outage

Which failures are detected through Generator Field Monitoring? How can Shaft Ground Monitoring stop failures before they occur? How can personnel trend and analyze variances with the Rotor Flux? What is the Return on Investment? What is the future of Predictive Maintenance?

Take three minutes to read the paper below to discover how you can protect the health of your generators.

Download paper