for failures

Overview

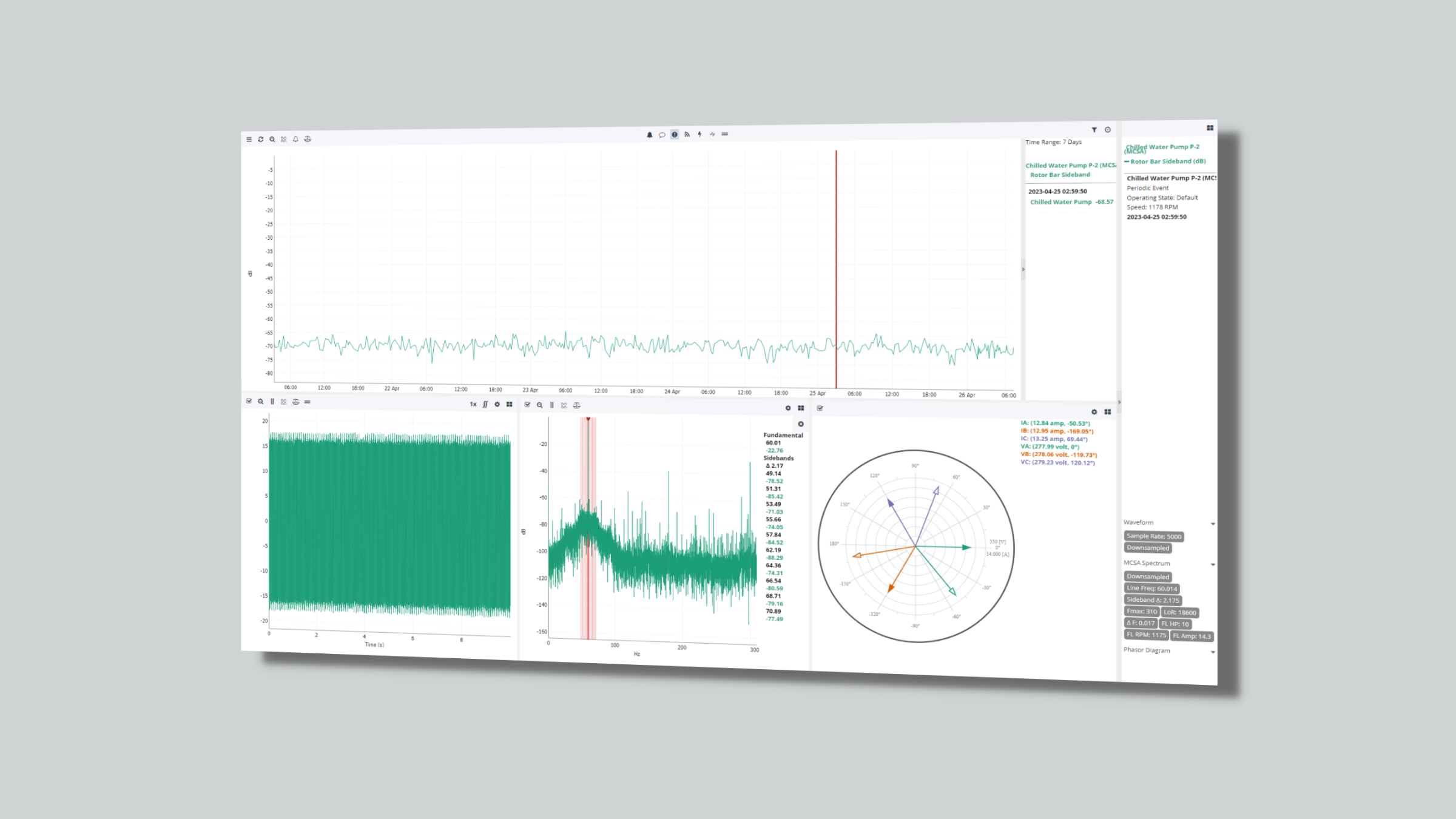

Cutsforth’s Electrical Signature Analysis (ESA) uses voltage and current signals to identify motor faults. The ESA toolkit for InsightCM™ computes features specific to electrical data and motors beyond phasor and waveform analysis.

Failure modes

- Rotor bar damage

- Misalignment

- Eccentricity

- Mechanical looseness

- Stator faults

- Bearing faults

- Power Quality Issues

Efficiency matters

ESA is cost effective. Monitor up to 9 motors on a single voltage bus with one acquisition device. Installation near Motor Control Centers (MCCs) minimizes cable lengths and installation costs.

Never miss a startup

Intelligent gating at the edge provides continuous monitoring while minimizing network bandwidth and storage requirements.

Read our article on Pumps&Systems.com about “Implementing Predictive and Prescriptive Digital Pump Maintenance Technologies“

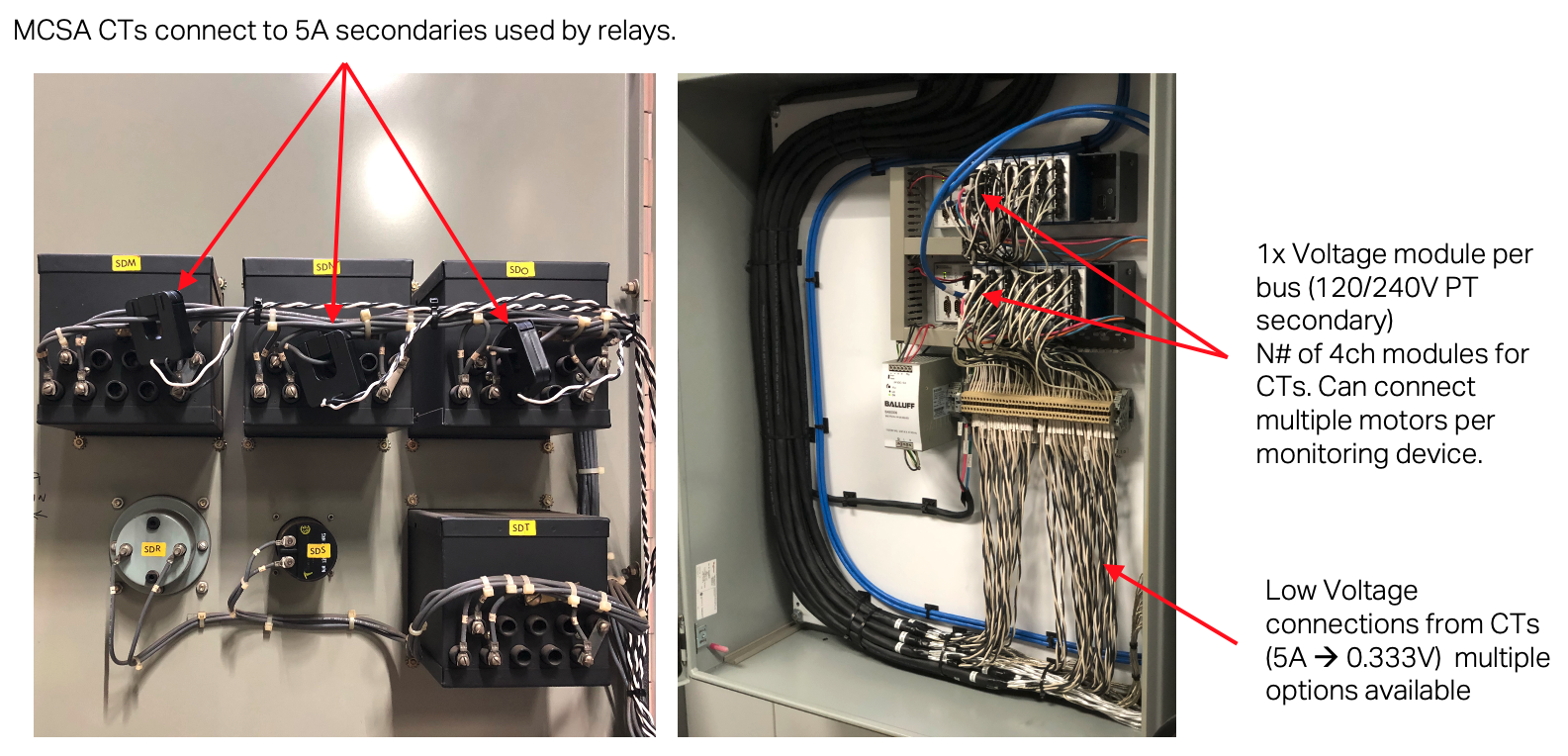

Make use of protective relay current transformers (CTs) and potential transformers (PTs) to simplify installation and necessary signal conditioning. You can also take advantage of existing infrastructure to minimize installation and sensing costs. If CTs and PTs are not present, make measurements directly.

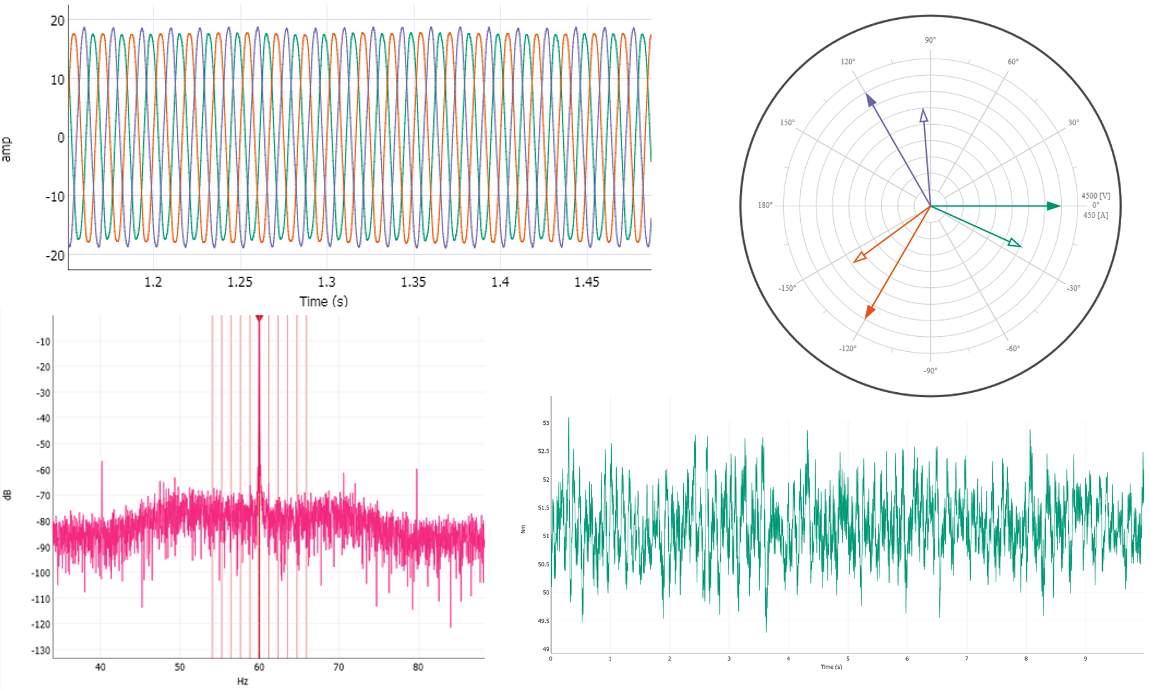

- Trend

- Waveform

- Spectrum

- High resolution spectrum

- Torque waveform

- Phasor diagram

- Envelope (amplitude demodulation)

- Park Clarke

Explore how this enriched solution uses voltage and current signals to identify motor faults including rotor-bar damage, stator faults, bearing problems, and more!